Ribbon Mixer Blending Cohesion

Diffusion mixing can also be affected by product cohesion. Cohesion can be the result of electrostatic forces as might be found with sulphur compounds, van der Waals forces which become more prominent as particles become smaller (typically <2 microns) and available surface area increases and moisture which can cause stable agglomerates to form. To overcome these various attractive forces and effectively disperse one solid in another, either a longer mixing time will be require or higher energy input which is often achieve by the addition of high speed agitators or choppers mounted in the side of the ribbon mixer.

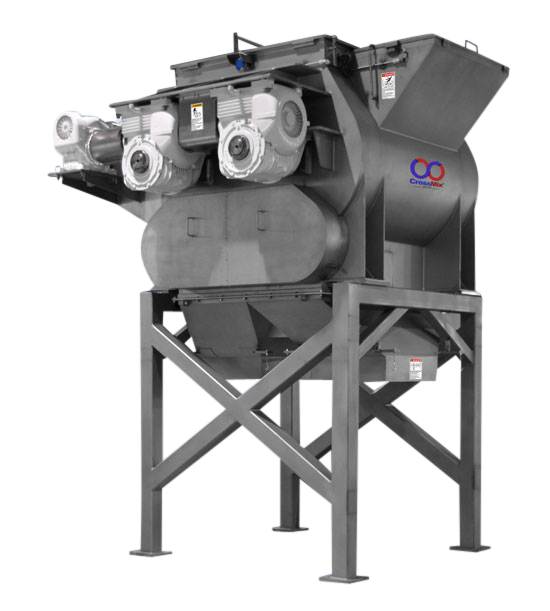

For special mixing applications such as powdered metals or friable materials, consider our Rota-Cone® Blenders or CrossMix® Fluidizing Mixers.

For viscous or heavy paste mixing we offer Double-Arm Mixers & Extruders.

Click to request a ribbon blender quote online or call 630-350-3012 to speak with an expert at Paul O. Abbe® to help you determine which design and size ball mill would be best for your process.

See our Mixing & Blending Options