Ribbon and Paddle Blenders

“Paul O. Abbe designs and manufactures ribbon blenders which are ideal for blending dry, free-flowing solids with bulk densities up to 70 pounds per cubic foot (1.1 g/cc) depending on material characteristics including, particle size, size distribution and particle shape (morphology), angle of repose, cohesiveness, and moisture level. Ribbon blenders are used for all dry foods products, nutraceuticals, protein powder mixes, dry juice mixes, chemicals, fertilizer, insecticides, colorants, resins and polymers. The moderate shear of the ribbon or paddle naturally breaks down lumps and agglomerates. Ribbon blenders are extremely efficient and economical.”

The double ribbon mixer design moves solids in two directions simultaneously and also rotationally to provide the mixing action. The inner ribbon mixer moves the solids toward the ends of the trough and the outer ribbons move solids toward the middle of the trough. When discharging the solids, the outer ribbons move the solids toward the center discharge valve.

- Ribbon blenders are effective down to about 25% of fill level. As long as both inner and outer ribbon flights are covered, the back and forth mixing action will occur.

- Lumps and agglomerates cab be broken down by the addition of high-speed lump agitators mounted through the side wall of the trough.

- Liquids can be added directly through the loading grate or with the addition of a liquid spray bar mounted along the length of the touch.

- Jacketing can be added for heating or cooling of the solids. The movement of the solids against the wall provides good heat transfer with the solids.

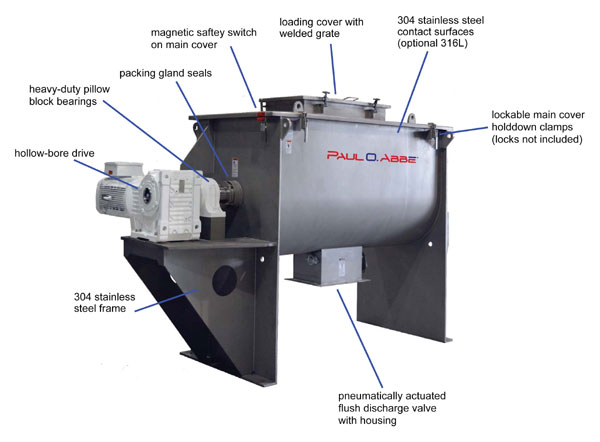

Standard Design:

Contact Materials: 304 Stainless Steel 316L optional

Interior Surfaces: Polished 180 Grit

Support Steel: 304 Stainless Steel

Exterior Surfaces: Glass Bead Blasted

Discharge: Swing away flush valve with pneumatic actuation

Working Capacities: 3 to 1,000 Cubic Feet

Drive: Hollow Bore SEW Eurodrive

Loading: Loading Cover(s) with Welded Grate

Safety: Magnetic Safety Switch(s) on Main Cover

- Lockable Stainless Steel Hold Down Clamps on Main Cover

Design Options:

• 316L Stainless Steel Contact Surfaces

• Heating or Cooling Jackets

• Custom Loading Hatches and Flanges

• Flush Bottom Ball Valve

• Liquid Addition Spray Bar

• CIP - Clean-In-Place Spray Nozzles

• XP Electrics

Controls: Soft Start or VFD in NEMA-12, 4, 4X or 7&9 Enclosures

• High Speed Choppers

• Purged Seals

|

CLICK HERE TO DOWNLOAD CAPACITIES AND DIMENSIONS |

Any blender can be raised from a few inches to 16 feet. All welded square tubular 304 stainless steel (epoxy coated carbon steel also available) with cross members and machined mounting pads for blender feet. Legs can also be drilled to accommodate electronic load cells. Front of stand is open for entry of bins, bulk bags and other containers. Available for all new or previously installed blenders.

Ribbon Blender working capacities from 1 to 515 cubic foot are standard. Ribbon mixers can be manufacturered up to 1,500 cubic foot capacity.

Recently shipping Ribbon Blender with all stainless steel with stainless steel counterbalance and stainless pneumatic piston assist.