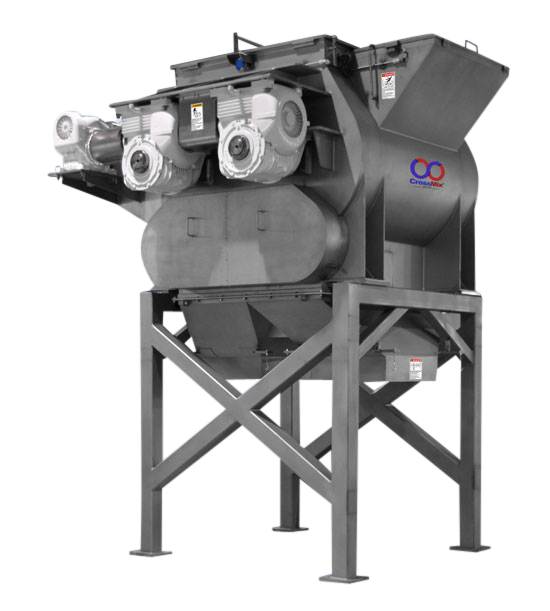

CrossMix® Fluidizing Mixer

The CrossMix® is a twin-paddle mixer that gently lifts and fluidizes solids in a weightless zone where particles of any size or shape can move freely and mix rapidly. Mixing can be completed in as little as 7 to 20 seconds. The CrossMix® is most beneficial for solids that require very high homogeneity, are fragile such as coffee, trail mix and crystals or solids that may smear with over mixing such as pigments or waxy or oily products.

.jpg)

LIQUID ADDITION and COATING is fast and efficient in the CrossMix® . Particles are separated in the weightless zone, exposing maximum surface area to allow liquid spray droplets to contact more particles more quickly. This can result in less liquid being used for coating and less agglomeration.

Discharges faster than it mixes: Two full-length bomb-bay discharge doors assure that the solid will not segregate during discharge. Multiple pneumatic cylinders assure positive closing and fast opening. Limit switches on each door signal that each door has opened for discharge and signals that the doors are closed and ready for the next batch.

Materials: Stainless Steel, Carbon Steel, Abrasion Resistant Steel.

Sizes: 0.2 to 176 cubic feet

Design Options:

• Heating or Cooling Jackets

• Liquid Addition

• Polished Contact Surface

• CIP - Clean-In-Place Spray Nozzles

• ASME Code Stamp

• XP Electrics

• High Speed Lump Breaking Pin Mill

• Purged Seals

![]() CLICK HERE TO DOWNLOAD CROSSMIX® MIXER CAPACITY AND DIMENSIONS

CLICK HERE TO DOWNLOAD CROSSMIX® MIXER CAPACITY AND DIMENSIONS