Ribbon Mixer Blending Bulk Density

Ribbon mixer are generally designed to operate with solids of bulk densities of 75 lbs./ft3 or less. This keeps us for the most part in the realm or organic products. Minerals and powdered metals have bulk densities of 90 lbs./ft3 to 500 lbs./ft3 and are better suited to mixing in tumble blenders, not only due to the higher horse powder required, but also due to the abrasiveness of the inorganic solids. Many oxides of metals such as ZnO will be of sufficiently low bulk density to be mixed in the ribbon blender. Don’t assume the bulk density by a products description alone. For instance, spice mixing may involve a very low bulk densities product and would be ideal for a ribbon blender. But, a spice blend based on salt, a mineral, may have a bulk density of 84 lbs./ft3.

Bulk density is extremely important but it should be recognizing that it comes in two forms; tapped and untapped.

Tapped bulk density is the fully settle and, consequently, highest density of a finely divided solid. Tapped bulk density, as the name implies, is the density obtained after a container of the solids is tapped repeatedly or vibrated to induce settling of the solids. This is the type of action that occurs during transportation of the solids in containers, drums or bags.

Untapped bulk density is the minimum density and will cause the solids to occupy the greatest volume. When the two densities differ significantly, care must be taken when considering the working volume of the mixer. It would be safe to use the highest density for power calculations and the lowest density for the total working volume. The variance between tapped and untapped density is most affected by the absolute density of the solids, particles size and shape. Heavier, symmetrical and large particles tend to settle quickly without vibration, but light, irregularly shaped and finely divided organic solids such whey protein powders can vary in bulk density by as much as 50%.

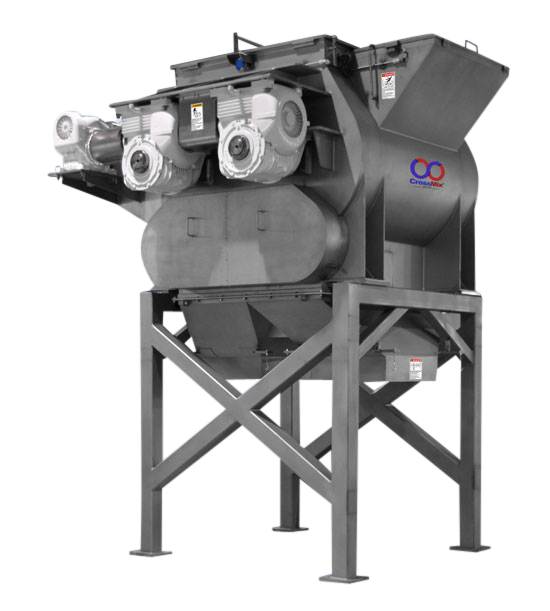

For special mixing applications such as powdered metals or friable materials, consider our Rota-Cone® Blenders or CrossMix® Fluidizing Mixers.

For viscous or heavy paste mixing we offer Double-Arm Mixers & Extruders.

Click to request a ribbon blender quote online or call 630-350-3012 to speak with an expert at Paul O. Abbe® to help you determine which design and size ball mill would be best for your process.

See our Mixing & Blending Options