Ribbon Blender Design Features & Options

Ribbon blenders are commonly used but they are not so universal that we can ignore their limitations. Ribbon blenders are very effective but only within a range of parameters. The below ribbon mixer characteristics should be considered based on the way a ribbon blender operates.

- Sanitary design improves discharge and makes cleaning easier and more thorough.

- Slide-gate discharge valve with pneumatic actuator (lab models IMB-1 and 2.5 are manual).

- 304 stainless steel contact surfaces, packing gland, support structure and chain guard.

- All internal and external welds are radiused, ground smooth, flush and pit free. 200 grit polish inside and out.

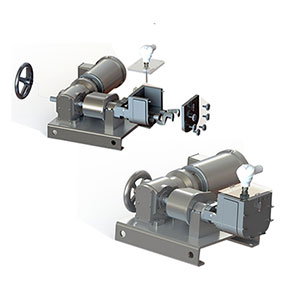

- Shaft packing gland housing is split for easy maintenance.

- Provision for gas or liquid purge.

- Sealed pillow block roller bearings.

- Heavy-duty Class-III gear reducer and chain drive.

- Fully welded 304 stainless steel agitator and shaft with flanged ends for easy removal.

- 1-, 2- or 3-piece hinged covers with removable grates. Limit switches* provided for each cover or grate section.

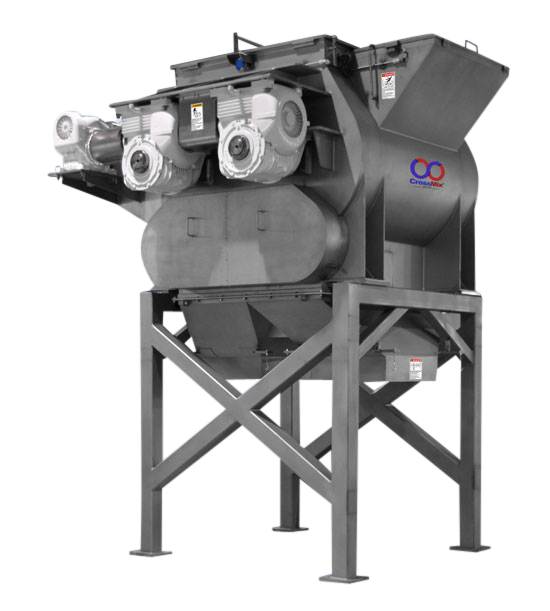

Any blender can be raised from a few inches to 16 feet. All welded square tubular 304 stainless steel (epoxy coated carbon steel also available) with cross members and machined mounting pads for blender feet. Legs can also be drilled to accommodate electronic load cells. Front of stand is open for entry of bins, bulk bags and other containers. Available for all new or previously installed blenders.

Ribbon Blender working capacities from 1 to 515 cubic foot are standard. Ribbon mixers can be manufacturered up to 1,500 cubic foot capacity.

Ribbon Blender Design Options:

- Extended legs

- Modified covers with various loading ports.

- Liquid addition spray bar and nozzles

- 304L or 316L stainless steel

- Paddle agitators or ribbon-paddle agitators

- Auger discharge

- End or multiple discharge points

- Ball valve or flush bottom plug valves

- High-intensity side-entering choppers

- Heating or cooling jackets including ASME code

- Product thermowell

- Internal vacuum design

- Explosion Proof Motors

- Higher HP drives

- Shaft-mounted or hollow-bore gear reducers

- Controls in NEMA-12, 4, 4X or 7&9 or purged

- Soft-start or variable frequency drives

- Load cells

For special mixing applications such as powdered metals or friable materials, consider our Rota-Cone® Blenders or CrossMix® Fluidizing Mixers.

For viscous or heavy paste mixing we offer Double-Arm Mixers & Extruders.

Click to request a ribbon blender quote online or call 630-350-3012 to speak with an expert at Paul O. Abbe® to help you determine which design and size ball mill would be best for your process.

See our Mixing & Blending Options