Discharging a Sigma Blade Mixer

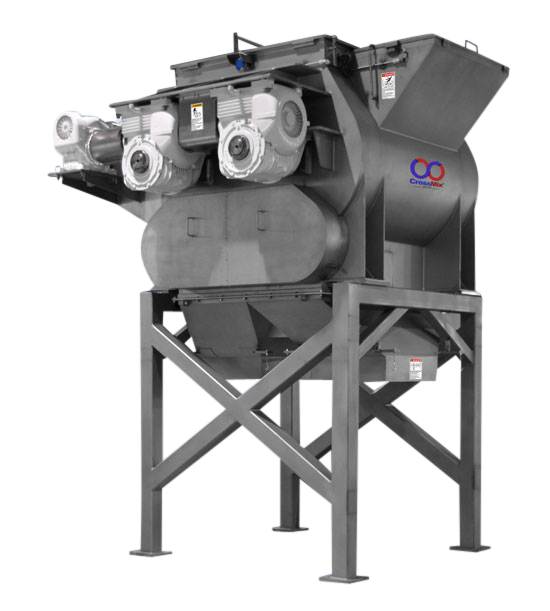

Designs for discharging a sigma mixer depend on the characteristics of the product and the need for process containment. There are three basic designs of discharge.

- Tilting discharge is done by rotating and tilting the bowl about 110° and dumping the product out. This is the most common method of discharging a sigma blade mixer especially for heavy masses and solids such as ceramics, powdered metals and carbon.

- Bottom discharge on sigma blade mixers can be large swing away doors in the bowl or free flowing liquid, flush bottom ball valves in the bowl bottom will facilitate discharge.

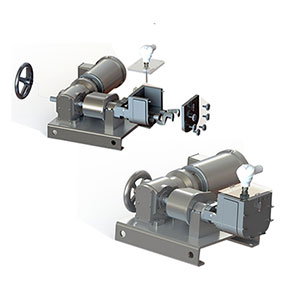

- Extruder or discharge screws can be used and are mounted where saddle would normally be to discharge a double arm mixer. During mixing the flighted screw runs backwards to keep product in the mixing chamber and to discharge the screw is reversed and purchased the product our through the screw barrel. These are not actually high-pressure extrusion screws but are used primarily for discharge. A discharge screw is ideal for keeping the process enclosed when the product cannot be exposed to air or the release of noxious fumes.

Request Price Quote

Click to request a sigma blade mixer online or call 630-350-3012 to speak with an expert at Paul O. Abbe® to help you determine which design and size ball mill would be best for your process.

See our Mixing & Blending Options